The Lawrence Berkeley National Laboratory, a.k.a. Berkeley Lab, is embarking on two initiatives—one concerned with low energy use, the other with performance under high-energy conditions—that could have long-range effects on how green building designers and engineers evaluate the performance of tomorrow’s most environmentally friendly materials.

On the low-energy side, California-based Berkeley Lab has broken ground on its long-awaited Facility for Low-Energy eXperiments on Buildings (FLEXLAB), which will contain new platforms for scientists, builders, architects and engineers to test a wide variety of building materials for their environmental characteristics. For higher-energy testing, the lab has also created its Advanced Light Source (ALS) mechanical testing rig, which researchers can now use to experiment on ceramic composites under ultrahigh operational temperatures.

Artist’s conception of new FLEXLAB modules via Berkeley Lab

Once construction is completed in late 2013, FLEXLAB will allow researchers to experiment with various combinations of building materials as integrated systems under real-word conditions. Materials to be evaluated include windows, walls, access floors, lighting, HVAC systems and other prototype elements. The interior spaces of FLEXLAB can also be reconfigured in separate testing zones or converted into office space, as needed.

“Buildings are responsible for about 40 percent of our nation’s greenhouse gas emissions,” said Ashok Gadgil, director of Berkeley Lab’s Environmental Energy Technologies Division at the Dec. 7 groundbreaking. “Finding new, advanced building technologies should help us save up to 80 percent on new construction.”

The four test beds that are being constructed will form the new exterior portion of FLEXLAB. One test bed designed for solar experiments can be rotated to align with the sun at any angle. Another bed, slated for large spaces and skylights, can include test materials up to two stories high. Two other test beds in an adjacent building were completed last month and are now in the start-up phase.

Artist’s conception of final FLEXLAB layout via Berkeley Lab

Altogether, the six test beds in the $16 million FLEXLAB complex will encompass 9,000 square feet of space and will be used to monitor the effects of outdoor weather, airflow and pressure, lighting and glare, and thermal conditions.

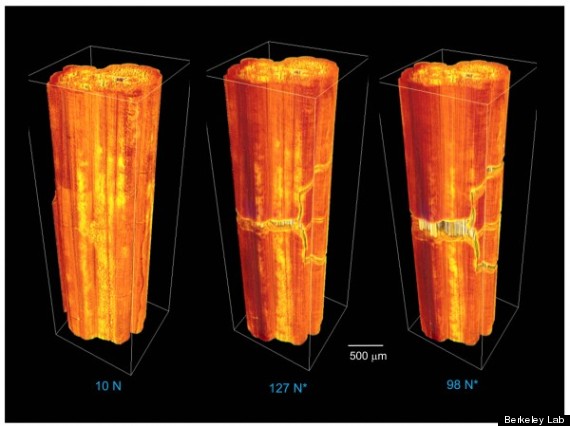

Meanwhile, Berkeley Lab’s new ALS rig will perform torture tests on ceramic composites at temperatures as high as 1,750 degrees Celsius. Using X-ray computed microtomography, researchers can monitor the growth of microcrack damage to determine the stress limits at which the compounds can retain their integrity and produce a nondestructive 3D image showing details as small as 1 micron across.

A CT scan showing microcracks forming on ceramic compounds at 1,750 degrees Celsius. Image via Berkeley Lab.

Although most of these high-performance ceramics are designed for use in turbines and hypersonic jet engines, they are increasingly being used as green building materials for their increased strength, lighter weight and ability to withstand corrosion from water, chemicals, oxidation and intense heat. Scientists hope the data from the ALS test rig can help produce even tougher, less brittle ceramic composites via the addition of reinforcing microfibers.