The transportation future is underway on 6.2 acres of graded mud next to a capped landfill off I-91's exit 33 in Hartford, Conn.

While it doesn't look like much now, when it's finished, Robert Bolduc's "Hartford Travel Center," under construction on the Northeast corner of Jennings Road exit, will house a first-of-its-kind hydrogen re-fueling pump for the region's first publicly available fuel cell vehicles.

"Who can argue about another energy efficient fuel? It's like motherhood and apple pie," says Bolduc, who requires staff to read Al Gore's climate change manifesto, "An Inconvenient Truth."

If all goes to plan, that pump, when it clicks on this summer, will be the first of a dozen expected to launch in the Northeast.

The effort is part of a collaboration between Toyota and Air Liquide to spark a market for fuel cell vehicles in the region.

The first asphalt has been laid for another station planned for installation in Braintree, Mass., on a re-graded Lumber Liquidators parking lot at 240 Wood Road.

Most of the pumps planned for the northern part of New England will be supplied with hydrogen trucked in from an Air Liquide distribution center in Littleton, Mass., that the Paris-based industrial gas giant is building on an acre of land it's leasing from Fiba Technologies, a Millbury, Mass.-based gas equipment supplier that's manufacturing the high-pressure tubes that will store hydrogen onsite at the fueling stations. Another distribution center planned for "the New York City area" will supply stations in the southern part of the corridor.

The work is significant, because increasing numbers of technologists predict many of us will be driving fuel cell vehicles in the future. But the hydrogen refueling infrastructure must be built before any of these cars can hit the road.

California, which leads the U.S. in hydrogen stations, has 13 pumps currently open to the public. The Northeast has two - a SunHydro dispenser at the Wallingford, Conn., headquarters of hydrogen generator supplier, Proton Onsite; and a call-ahead pump at the Billerica, Mass., headquarters of fuel cell maker Nuvera. Japan, meanwhile, has opened 81 public hydrogen stations, and Germany, 18.

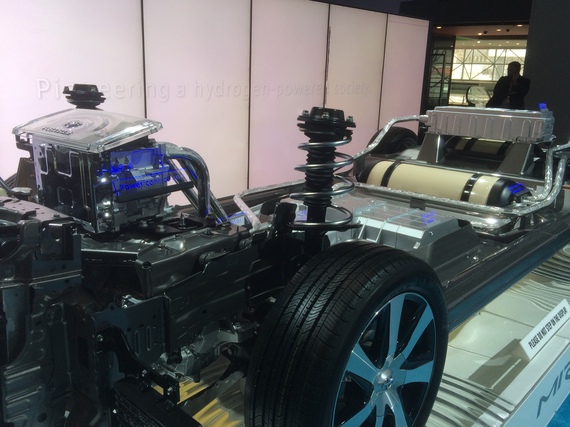

The new stations in the Northeast U.S. are being built to refuel the Mirai, Toyota's fuel cell electric vehicle (FCEV), available now in California but slated for delivery to the Northeast later this year. The pumps, however, are compatible with any of the other publicly available FCEVs, including Hyundai's Tucson; and Honda's Clarity.

Hydrogen Economics

Air Liquide is one of three bidders on a $450,000 grant from Connecticut that calls for the construction of two hydrogen fueling stations in Hartford. But the grant's administrators have yet to receive from carmakers specific FCEV production timelines the state requires before any final decisions on funding can be made.

That's because, to make money selling hydrogen, which costs roughly the same as gasoline, each station needs at least 100 FCEVs stopping by to fill up. While planned municipal fleet leasing alone could enable standalone stations to surpass that threshold, doing so requires OEM production commitments.

"We expect local economic development associated with the manufacturing and maintenance of FCEVs and their refueling stations," says Joel Rinebold, director of the energy department at the Connecticut Center for Advanced Technology, which will recommend a winning bidder to the state.

Subsidies help: Hydrogen pumps cost between $1 million and $3 million to build.

Adding a hydrogen dispenser to a traditional gas station/convenience mart, opened to both private- and government-owned fleets - aside from replicating the conventional fill-up experience - can help absorb costs. (Margins on all retail fuel sales are thin: Nearly 70 percent of a gas station owner's profits come from food and merchandise purchases.)

FCEV Edge

FCEVs hold several advantages over battery electric vehicles (BEVs). While both are considered zero emission vehicles (ZEVs), FCEVs can travel farther - about 300 miles - on a single tank of hydrogen than BEVs can on a single charge. And it only takes minutes to refuel an FCEV compared to the hours to days it takes to fully recharge an all-electric car. Plus, FCEVs perform the same regardless of the amount of hydrogen in their tanks; whereas BEVs' performance degrades when their batteries run low.

FCEVs also tip the scales as greener technology: While most purified hydrogen needed for cars now is made from burning natural gas, BEVs plug into a grid that gets 33 percent of its power from burning coal. Emissions-free production using solar- or wind-powered electricity to separate the hydrogen from oxygen in water - a process called electrolysis - is also coming online.

While Air Liquide will truck in most of the hydrogen needed for the Northeast stations, H2 for the Braintree pump will be produced by a water electrolyzer from Proton Onsite, which will be powered in part by solar arrays owned by the Braintree Electric Light Department (BELD).

Air Liquide could tap the methane Hartford landfill produces naturally and convert it into hydrogen to supply the pump at the travel center. While not without emissions, this landfill-to-gas method is considered a carbon neutral way of producing hydrogen, because it prevents a ubiquitous and more damaging greenhouse gas - methane traps 86 times more heat than carbon dioxide does over 20 years - from otherwise escaping into the atmosphere.

Hartford landfill's methane is owned by DeltaPro Energy Inc., which is open to offers competitive with the price it could get from selling the power back to the local grid operator in two years when a power purchase agreement ends. "I'd absolutely take a look at it," said Joseph G. Merckel, DeltaPro's owner. "I actually thought about a hydrogen gas opportunity awhile back, but I didn't know who to sell it to."

Having available funding and an awareness of hydrogen's safe, clean energy potential is why Hartford and Littleton lead the Northeast build-out.

"Hydrogen is safer than gasoline, propane or compressed natural gas," Robert J. Davidson, a former fire marshal turned hydrogen safety expert and founder of Davidson Code Concepts, emphasizes. "Anyone familiar with the modern standards understands this."