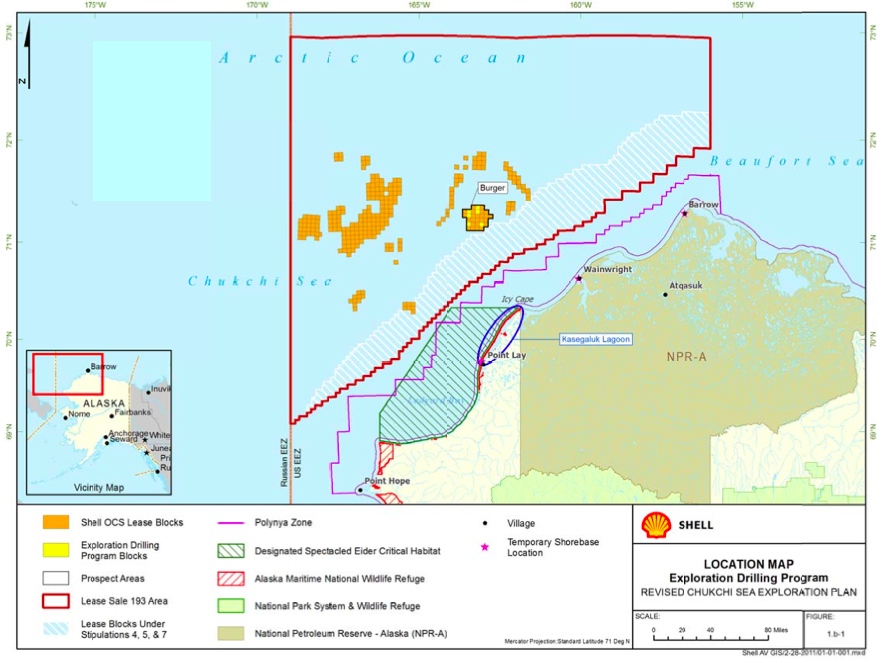

Shell announced yesterday that it began drilling its Burger prospect 70 miles offshore Alaska's northwest coast that morning at 8:30 am eastern time. The drillship Noble Discoverer is being used for this prospect, which is in about 150 feet of water. The Bureau of Safety and Environmental Enforcement (BSEE) gave the go-ahead to Shell on August 30 after years of planning, legal challenges, and great environmental concern. The environmental concern, obviously, continues.

In the offshore Arctic, the drilling season is short due to sea ice and harsh conditions that prevail most of the year. The plan for the development in this region will be to conduct "tophole" operations during the first drilling season, returning the next year to finish the wells. This drilling protocol has been established to avoid conditions that could jeopardize the safety of the operation, increasing the risks to this delicate environment.

Sea ice is a huge threat to operations in the Arctic offshore. Because the water is shallow, at 150 feet, huge sheets of ice actually drag across the sea floor, called "ice scour". Because of ice scour, the seafloor equipment, especially the blowout preventer (BOP), is threatened with destruction from the incredible forces created by sea ice being pushed across the bottom. To mitigate against this very real risk, shell designed a "mudline cellar" that actually puts the top of the BOP, which could be as tall as a 5 story building, below the seafloor, protecting it from the ice.

To conduct the tophole operation, a pilot hole is drilled to around 1,300 to 1,400 feet below the sea floor to make sure there are no shallow pockets of gas that could blow out, a common problem in the offshore. Once the pilot hole is successfully drilled, the mudline cellar is constructed, followed by the conductor pipe, which forms the foundation for the BOP. The well will then be plugged for the winter, to be re-entered and completed the following year. As an additional safety precaution, the BOPs being used in this region will have two blind shear rams installed, rather than a single one that failed so catastrophically on BP's Macondo well in 2010. Shell has produced a video that describes the construction of this element in Arctic drilling.

Because the water is much shallower than in deepwater operations, these wells are technically more straightforward to drill. Because the control point, the BOP, is much closer to the drillship than in deepwater, monitoring the well is easier, and trip time to get to the seafloor much shorter. However, environmental threats, especially ice, can cause catastrophic accidents if not managed properly. Shell is required to keep ice management vessels on site to monitor movement of sea ice. Once the drilling operations reach hydrocarbon bearing zones, well containment and capping equipment must also be on site, a safety precaution not required in the Gulf of Mexico. There, it must be on standby onshore, ready to deploy with hours of notice.

There are many questions to be asked about why our demand for hydrocarbon-based fuels is so great that we are now drilling for hydrocarbons in some of the most harsh conditions in the world. Oil companies are spending billions of dollars to access huge hydrocarbon resources in these conditions for two reasons: first, they can, and second, they make money doing it. It's not a question of can we do this; the real question is why. This is a policy issue. The problem, though, is that with no comprehensive energy policy that establishes national priorities for sustainable energy production and consumption, we are in this endless cycle of find it, burn it, find it burn it. It's just that finding it is getting harder, more expensive, and carries huge risk for environmental catastrophe.

It's not a matter of if there be a collision with ice or some other issue that could threaten the environment here, it's when. I take some comfort that this operation is being managed by Shell, who sets the gold standard in offshore operations, but the risks in this region are great and must be carefully managed.

I will be following the progress of drilling in the Arctic offshore and reporting on it both on Huffington Post and my environmental and energy blog, this small planet.